Siemens Capacitor Voltage Transformers are based on technology from Trench, a recognized world leader in the design and manufacture of high voltage equipment for application on electric utility and high energy industrial systems.

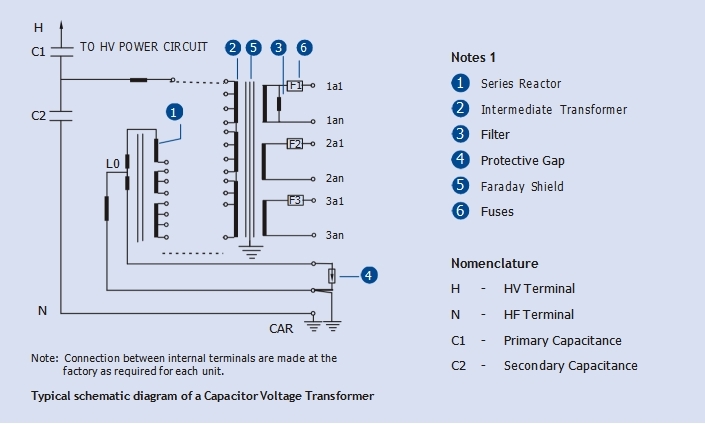

Capacitor Voltage Transformers convert transmission class voltages to standardized low and easily measurable values, which are used for metering, protection and control of the high voltage system. As such, the need for accurate and reliable voltage transformation is essential. Additionally, Capacitor Voltage Transformers serve as coupling capacitors for coupling high frequency power line carrier signals to the transmission line.

Today, Siemens is a world-wide leader with an entire range of instrument transformers from 72.5 kV to 800 kV covering:

The Siemens factory in Aurangabad fulfils the demand of our customers for highly reliable Capacitor Voltage Transformers.

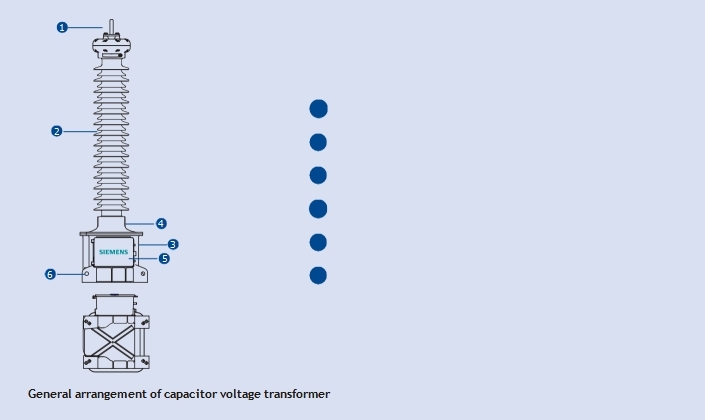

Siemens CVT's consist of two primary assemblies; the high voltage capacitor sections and the base box,housing the electro-magnetic components.

Series connected capacitor elements, housed in porcelain shells, each hermetically sealed, are referred to as capacitor sections. The dielectric of the capacitor elements is made up of high quality polypropylene film/paper and impregnated with highly processed synthetic fluid. Each capacitor section is equipped with a stainless steel bellow which will allow the synthetic fluid to expand and contract with changes in ambient operating temperature while maintaining the hermetic sealing. It is over these capacitor sections that most of the high voltage will be dropped.

A tap voltage (approximately 5-12 kV depending on type) is taken from the lowest capacitor section and fed to an electromagnetic circuit in the cast aluminum base box. The base box contains the intermediate transformer which will provide the final output voltages via multiple tapped secondary windings, series compensating reactor and ferro- resonance control circuitry. The base box is filled with dried mineral oil, protecting the components from environmental deterioration

Ferro-resonance is simply and effectively controlled by utilization of low flux density designed magnetic circuitry and a saturable reactor controlled damping circuit connected across the secondary winding. The ferro-resonance suppression circuit does not adversely affect transient response.

| Highest System Voltage(kV rms) | One minute power frequency withstand voltage (kV rms) | Impulse withstand voltage (1.2/50µs) (KVp) | Switching Impulse withstand voltage (250/2500 µs) (KVp) |

|---|---|---|---|

| 72.5 | 140 | 325 | - |

| 123 | 230 | 550 | - |

| 145 | 275 | 650 | - |

| 245 | 460 | 1050 | - |

| 420 | 630 | 1425 | 1050 |

| 765 | 975 | 2100 | 1550 |